In FDDWorX, a fault is a rule or expression that is based on time, a change of state, and a combination of any parameters related to a particular piece of equipment, that defines the circumstances under which the equipment is not operating to specification. For example, if a chiller is supposed to be able to cool a room by 1 degree every 5 minutes, it could be considered in a “faulted” state if after 30 minutes it has cooled the room by only 2 degrees. The chiller in this case is not necessarily broken, but something preventing it from operating at ideal efficiency. This can be quantified as a “fault”, and users can be notified when such conditions occur. You to add your own equipment faults and diagnostic models as they relate to your particular industry or application.

Faults are defined in the the Workbench using the Rules Editor, which integrates with the Expression Editor to offer a variety of functions in different categories including arithmetic, relational, logical, bitwise, string and date/time.

When you define a fault for use with FDDWorX:

Each fault is associated to a rule that drives/triggers this fault.

If each rule is associated to an output register, the configurator needs to either be able to get that output register from the rules engine when selecting it, or be able to derive the output register address from the rule name.

To define a fault, follow these steps:

In the the Workbench, open AnalytiX Catalog by clicking its Project Explorer provider button.

Expand localhost > AnalytiX > Assets to show the asset tree.

Expand the asset tree until you reach the equipment to which you want to add a fault.

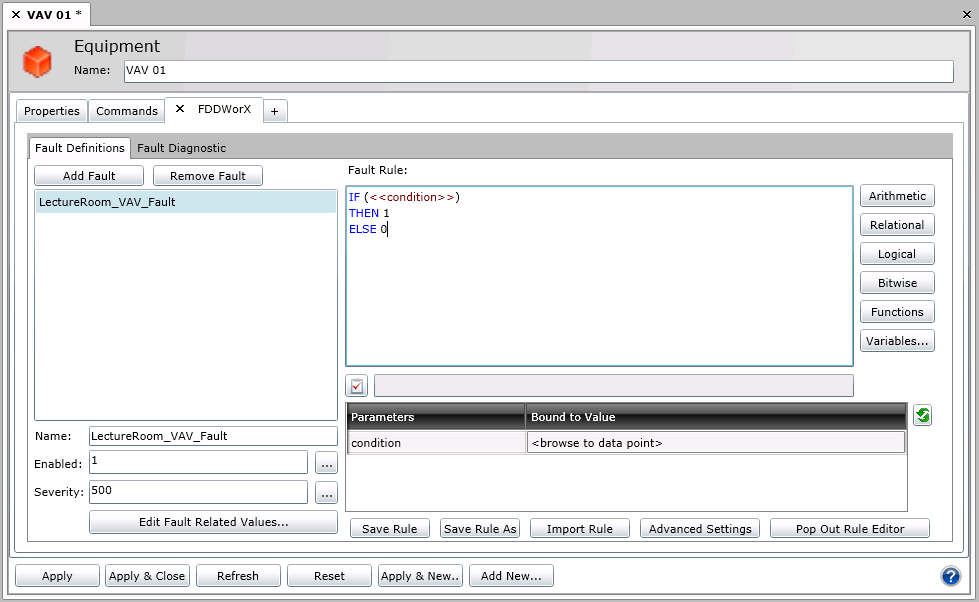

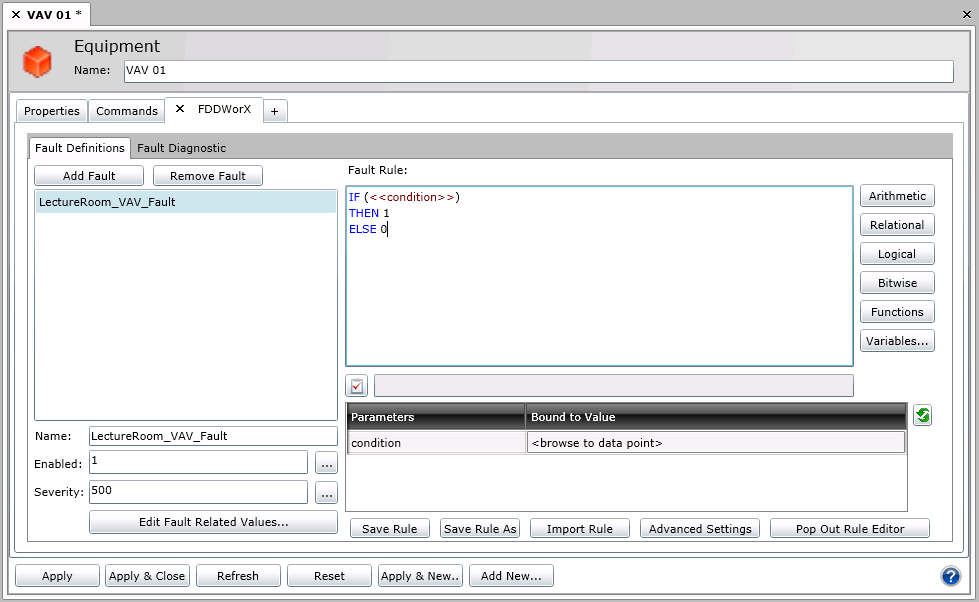

Click on the tab that has the plus sign (+) on it. From the Add New drop-down list, select FDDWorX. This adds the FDDWorX tab, with the Fault Definitions sub-tab on top.

Click the Add Fault button to add a fault. The sub-tab looks something like the following:

Fault Definition Example

Define faults as described in the Fault Definitions Tab topic.

Then map the equipment faults to a diagnostic model as described in the Fault Diagnostic Tab topic. Note that your diagnostic models must be created before you can complete this step.

See also:

Fault Detection and Diagnostics